The universal

BA 3

Machining center BA 3

PRODUCTIVITY

PRODUCTIVITY

| Loading/unloading in parallel to machining time

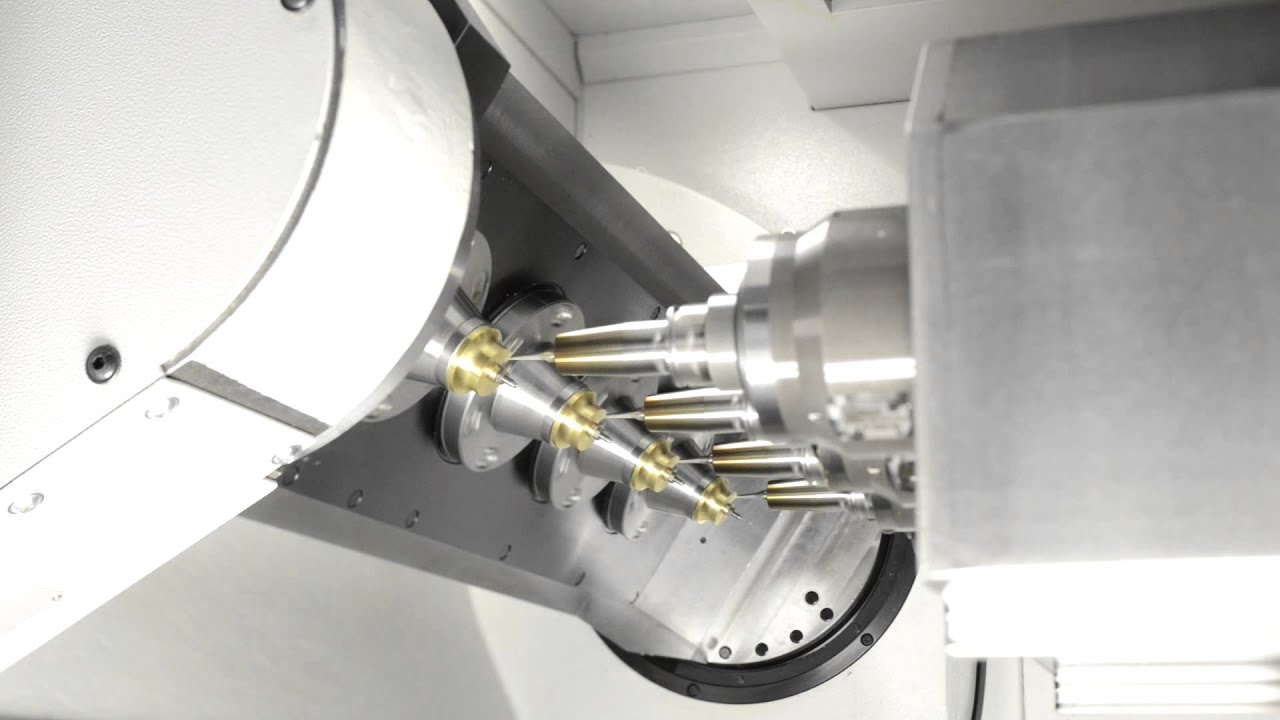

| Maximum productivity through multi-spindle capability

QUALITY

QUALITY

| High machine rigidity due to patented monoblock design

EASE OF USE

EASE OF USE

| Multi-touch control panel

| Tool control system

FLEXIBILITY

FLEXIBILITY

| Flexible automation solutions

| Customizable machine configuration

| Integrated loading module possible

ERGONOMICS

ERGONOMICS

| Accessibility to the workspace

| Clear visibility of machining process

ENERGY EFFICIENCY

ENERGY EFFICIENCY

| Highest energy efficiency (50% less energy used per part vs single-spindle)

SERVICE

SERVICE

| Fully integrated data management through life data

WORKPIECES

WORKPIECES

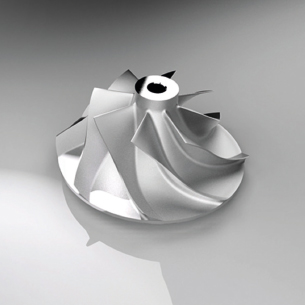

| Impeller

| Brake caliper

| Scroll compressor

| ABS valve body

TECHNICAL DATA

| DESCRIPTION | BA 311 | BA 312 | BA 321 |

|---|---|---|---|

| Spindles | 1 | 2 | |

| Spindle distance | – | 300 mm | |

| Speed range | 1-10,000 min-1 (1-17,500*) | ||

| Power (per spindle) | 32 kW | ||

| Torque (per spindle) | 72 Nm | ||

| HSK interface | HSK-A63 | ||

| Workspace X | 550 mm | 300 mm | |

| Workspace Y | 500 mm | 450 mm | 500 mm |

| Workspace Z | 375 mm | ||

| Interference circuit 4th axis | Ø 575 x 830 mm | Ø 475 x 830 mm | Ø 575 x 830 mm |

*optional

| DESCRIPTION | BA 322 & BA 322i | BA 341 | BA 342 & BA 342i |

|---|---|---|---|

| Spindles | 2 | 4 | |

| Spindle distance | 300 mm | 150 mm | |

| Speed range | 1-10,000 min-1 (1-17,500*) | 1-40,000 min-1 | 1-20,000 min-1 |

| Power (per spindle) | 32 kW | 13 kW | 18 kW |

| Torque (per spindle) | 72 Nm | 8 Nm | 17 Nm |

| HSK interface | HSK-A63 | HSK-E50 | HSK-A40 |

| Workspace X | 300 mm | 150 mm | |

| Workspace Y | 450 mm | 500 mm | 450 mm |

| Workspace Z | 375 mm | ||

| Interference circuit 4th axis | Ø 475 x 830 mm | Ø 575 x 830 mm | Ø 475 x 830 mm |

*optional

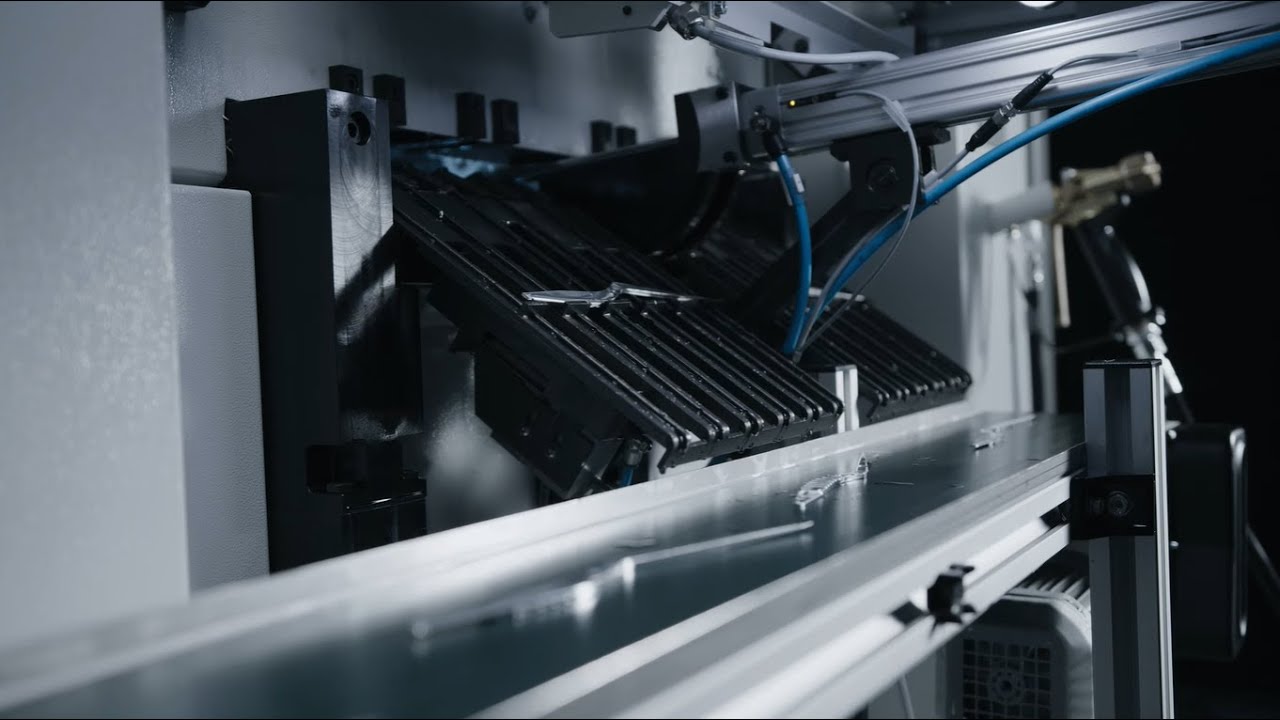

Integrated Automation

Why order and commission machine tools and automation separately? This usually only adds to the complexity of the process. As Technology People, we equip CNC machining centers of certain sizes with integrated automation to create self-sufficient production cells and supply them to you ready for connection as a plug & play solution.

Reference parts