TECHNOLOGY INSIGHTS

We would like to give you an insight behind the scenes at SW. On this page, we regularly publish case reports and feature articles about our daily work with and for our SW customers. When can we write our joint success story?

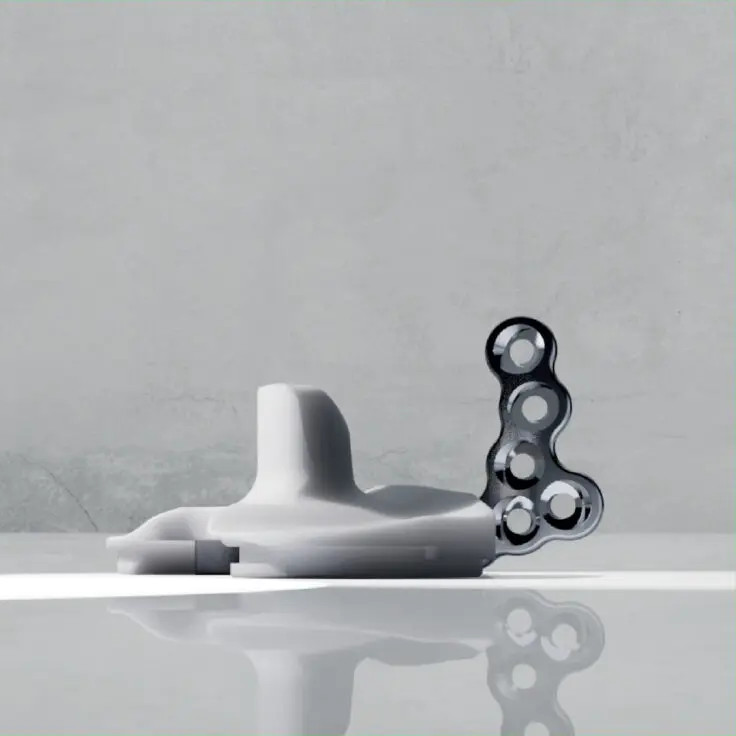

Tecomet boosts poly manufacturing with SW’s multi-spindle technology

Multiple part sizes and multiple configurations, high quality requirements with tight tolerances, complex production processes, and high volumes that must be manufactured as quickly and efficiently as possible: poly manufacturing for the orthopedics industry faces several challenges. The Irish expert Tecomet relies on two-spindle machining from Schwäbische Werkzeugmaschinen GmbH (SW), which helps to increase their knee implant production per operator and achieve an overall equipment efficiency increase.

Is Automation the Answer in Alleviating U.S. Manufacturing Labor Shortages?

Manufacturing employers are facing a jobs crisis. This comes as the US Census Bureau [...]

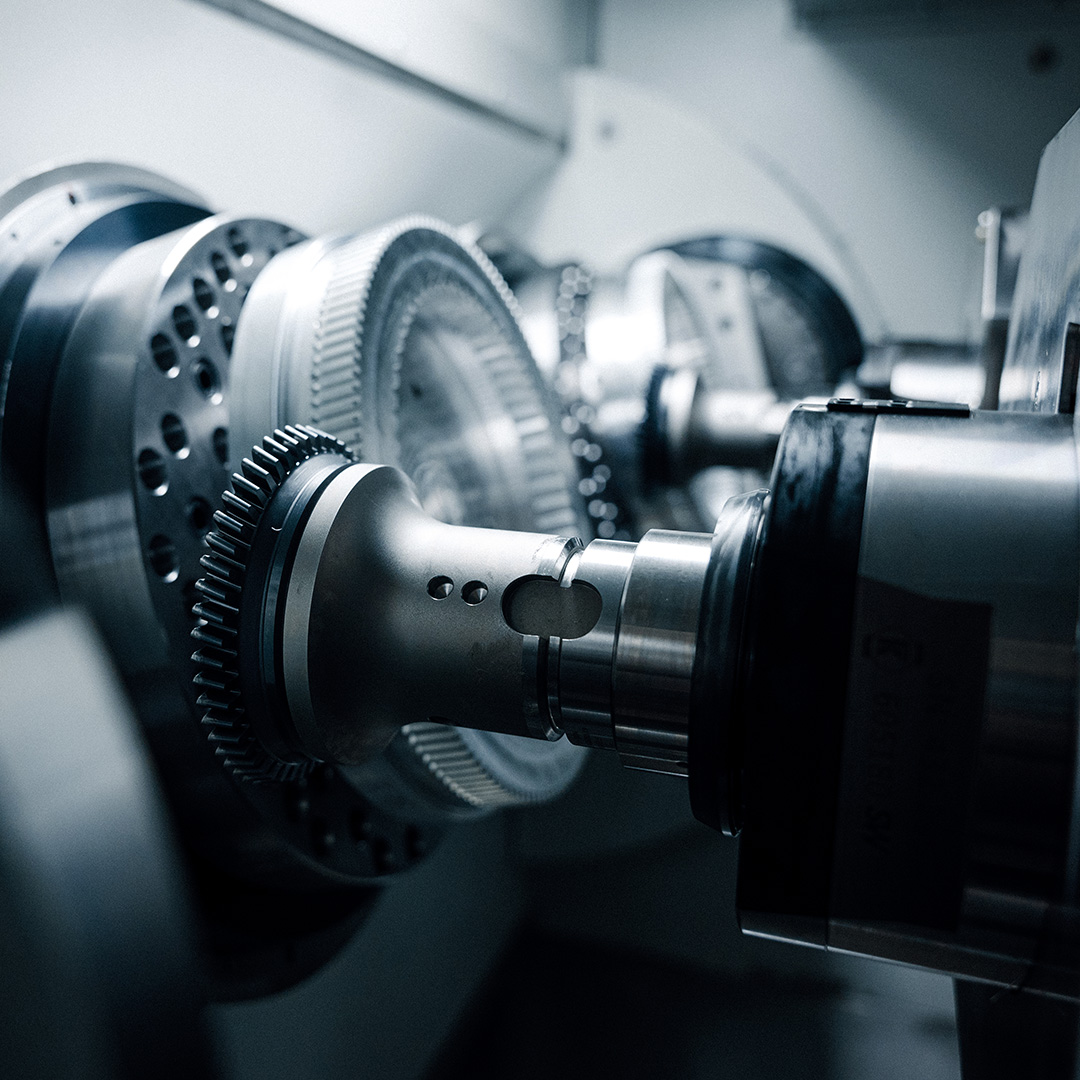

Power Skiving

First provider of power skiving on a multi-spindle machining center. In today's world, innovation is the key to success. With the introduction of power skiving on our multi-spindle machining centers, we are taking gear cutting technology to a new level. Higher productivity, lower costs, sustainable production! Find out more about this technology and its efficiency.

Efficiency of friction stir welded components

Das Rührreibschweißen, auch bekannt als Friction Stir Welding (FSW), ermöglicht eine feste Verbindung von Metallteilen ohne Schmelzebildung durch Erwärmung und plastische Verformung mittels rotierendem Werkzeug. Die Integration dieses Verfahrens bei SW-Baureihen ist grundsätzlich möglich und bietet Effizienzsteigerungen durch die Kombination mit Zerspanungsoperationen in Bearbeitungszentren.

Big parts with equally big challenges: Giga castings in CNC machining

The revolution in automotive production: Giga-castings in die casting are changing the production of structural components. Find out why CNC machining of these gigantic components is a complex challenge and what innovative solutions the industry is developing to meet the requirements.

How to Overcome Medical Device Supply Chain Volatility and Meet Increasing Demand

Medical device supply chain vulnerabilities have been accentuated in recent years, [...]

HAL expands new production line with SW equipment

For a new production line for machining cylinder crankcases, HAL Automotive GmbH relies on machines and automation from Schwäbische Werkzeugmaschinen GmbH - and thus realizes the entire project in less than a year.