CONSTRUCTION AND AGRICULTURAL MACHINERY:

Precise production of large components

Modern construction and agricultural machinery is characterized by robustness, power and energy efficiency. In the production of the sometimes very large components for the drive train, the working hydraulics and the mechanics, reproducibility and flexibility in micrometer-precise machining are essential. By achieving this, manufacturers increase the performance and service life of construction machinery, excavators, tractors, combine harvesters and many other mobile machines.

Wide range of workpieces: from small to extremely large

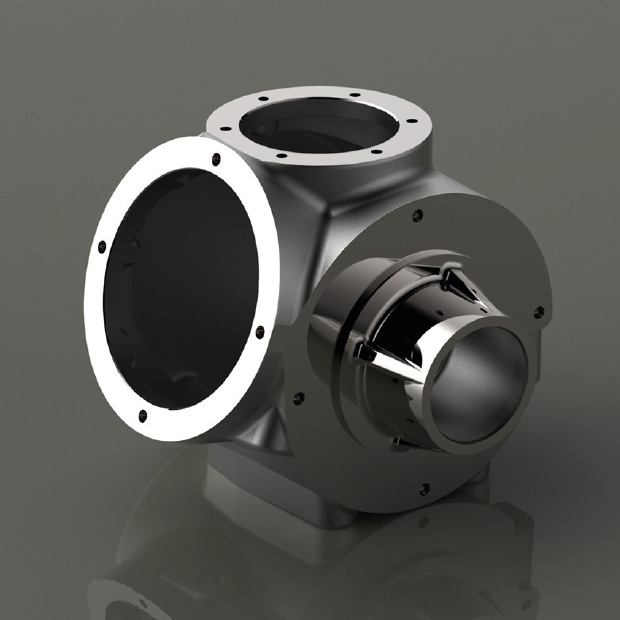

CNC machining centers from SW handle the precise machining of workpieces of various sizes from a variety of materials. All SW CNC machining centers follow the same design principles and the same operating philosophy. In this way, you standardize your production machinery and reduce training and maintenance costs. For example, our customers manufacture components for:

Exhaust systems |

Brakes |

Suspension and steering |

Engine and transmission components |

Drive trains|

and much more |

Find the right machine for your applications

Agriculture and Construction Concepts for Long Service Life

Flexible, precise, traceable

The key is CNC machining centers from SW. They perform 4- and 5-axis machining of steel, cast and forged parts quickly and precisely in workspaces up to 1,500 x 900 x 650 mm in size. Each machining step is documented down to the NC block level, ensuring complete traceability. In this way, manufacturers of construction and agricultural machinery combine transparency with manufacturing quality and precision with energy efficiency.

Large components

Quickly manufactured

SW offers CNC machining centers specially designed for machining large workpieces. They provide extra large workspaces. You do not compromise on precision and processing speed. Automation solutions precisely tailored to your large workpieces load and unload your machine tools and self-sufficient production cells fully automatically. We are also happy to realize complete production lines for highly efficient complete machining of component families with workpieces in different sizes.

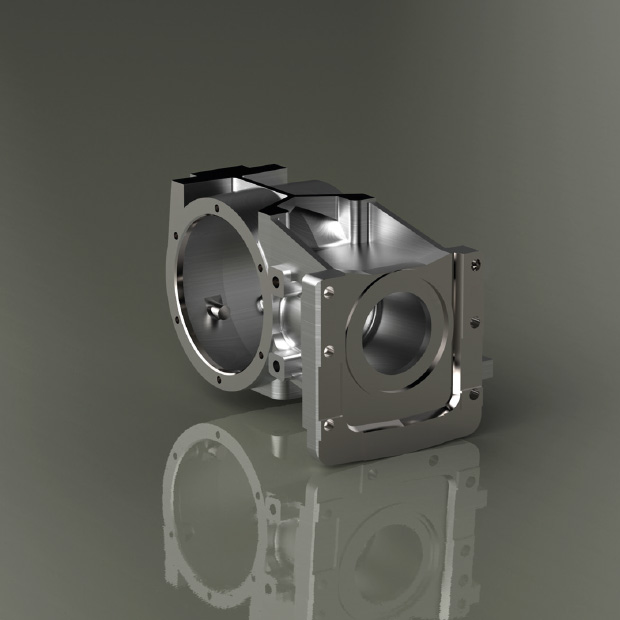

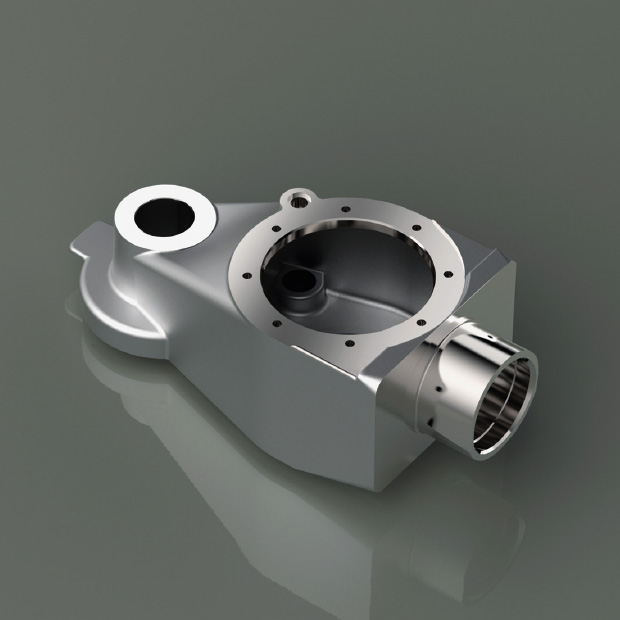

Reference parts