Automotive industry:

Managing volatility and traceability economically

Never before have TIER 1 and TIER 2 automotive suppliers had to compensate for greater volatility and shorter life cycles. The production volumes required by automobile manufacturers fluctuate enormously. At the same time, they expect the shortest possible ramp-up times for new components and the complete traceability of all components.

One partner

for all workpieces

Steel, cast iron, aluminum, titanium and alloys, small or large, drilling, milling or friction stir welding: On CNC machining centers from SW you can machine your components completely, with high precision and with the lowest unit costs.

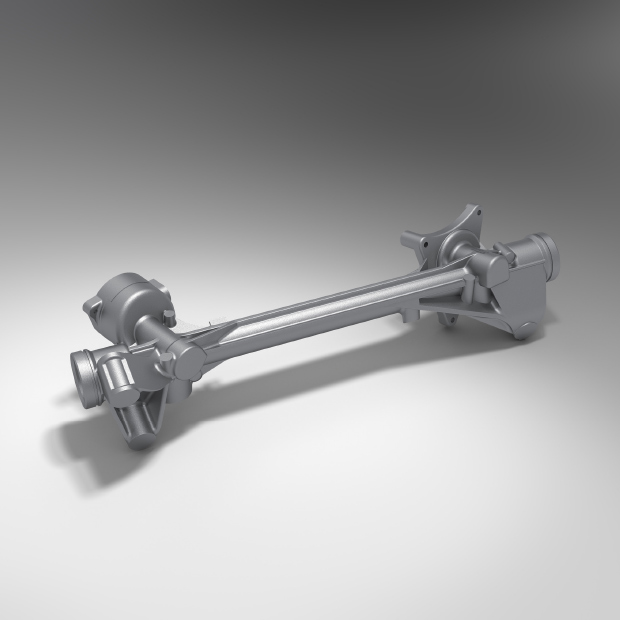

Wheel suspension + steering components |

Brake components |

Transmission components |

Motor & pump housings |

Structure & frame components |

Components for electric drives |

and much more |

System Solution by SW for Customer Schabmüller Automobiltechnik GmbH

60 percent shorter cycle times with multi-spindle machines

For us, the focus is on the economical production of your workpieces: from single- or multi-spindle machining centers to stand-alone production cells, the linking of various process steps, and complete production lines: With a four-spindle machine, for example, you reduce the cycle time per workpiece by up to 60 percent. They also save up to two-thirds on space requirements. Our CNC machining centers with linear motors are among the fastest systems in the world, leading in efficiency and quality in automotive production. We are also at your side when it comes to getting started with electromobility.

Ready for the

Digital

Transformation

SW’s machining centers and system solutions for the automotive industry already integrate seamlessly into IoT technology such as data tracking and traceability with digital services. This means you can increase the sustainability of your automotive production and be ready to better manage volatility and increased OEM requirements. Learn more about our machines, automation solutions and services.

Reference parts