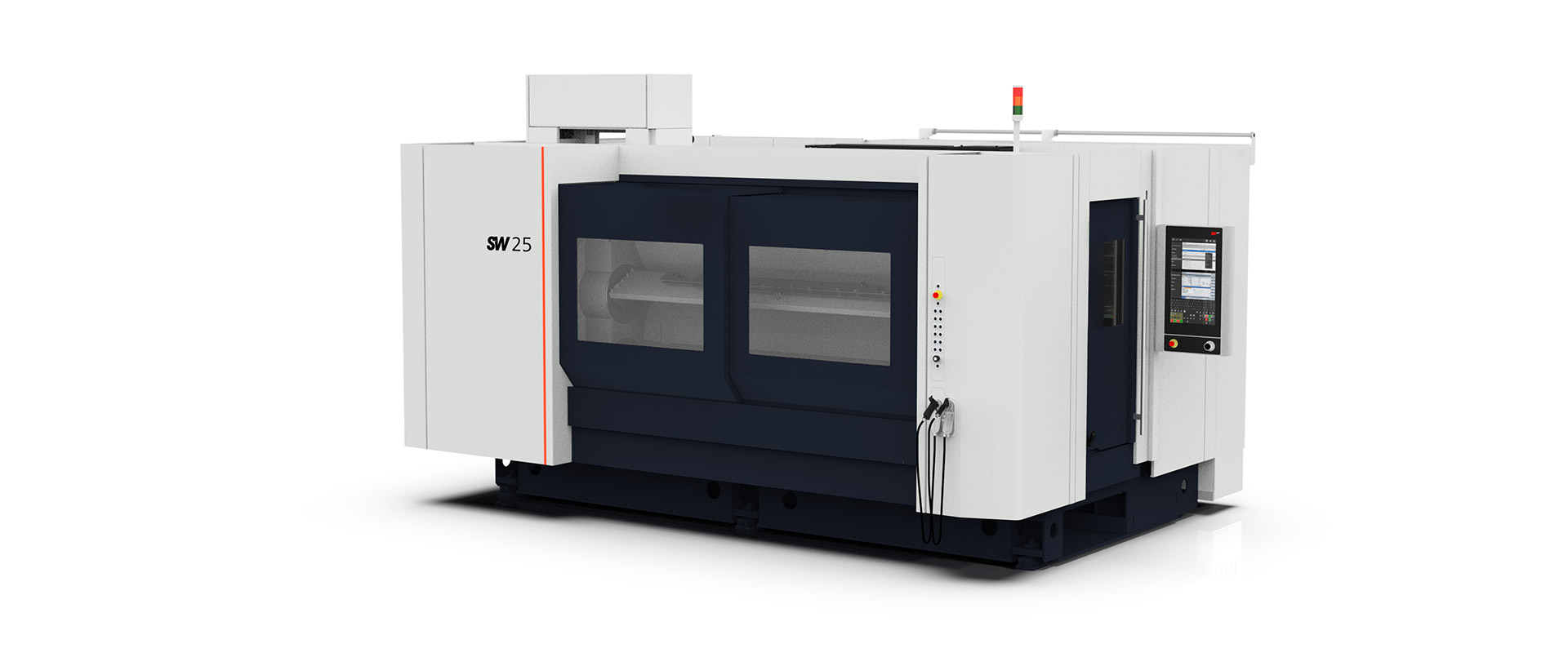

The Long

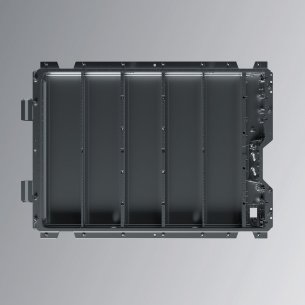

BF 25-22S

Machining center BF 25-22S

PRODUCTIVITY

PRODUCTIVITY

| Loading/unloading in parallel to machining time

| Maximum productivity through multi-spindle capability

| Highest dynamics due to linear drive technology

QUALITY

QUALITY

| Specialized for long components like extrusion profiles

EASE OF USE

EASE OF USE

| Multi-touch control panel

| Tool control system

FLEXIBILITY

FLEXIBILITY

| Flexible automation solutions

| Customized machine configuration

| Independent z axes

ERGONOMICS

ERGONOMICS

| Accessibility to the workspace

| Clear visibility of machining process

ENERGY EFFICIENCY

ENERGY EFFICIENCY

| Highest energy efficiency (-50% compared to single-spindle)

SERVICE

SERVICE

| Fully integrated data management through life data

WORKPIECES

WORKPIECES

| Side and cross members

| Battery housings

| Sills

| Crash profiles

| Guide rails

OVERVIEW OF THE DATA

| DESCRIPTION | BF 25-22S | ||

|---|---|---|---|

| Spindles | 2 | ||

| Spindle distance | 500 mm | ||

| Speed range | 1-17,500 min-1 | 1-40,000 min-1 | |

| Power (per spindle) | 35 kW | 18 kW | |

| Torque (per spindle) | 72 Nm | 11.5 Nm | |

| HSK interface | HSK-A63 | HSK-E50* | |

| Workroom X | 2,500 mm | ||

| Workspace Y | 400 mm | ||

| Workroom Z | 400 mm | ||

| Interference circuit 4th axis | Ø 500 x 2,700 mm | ||

*optional

Reference parts