Loading unit: Run your production for hours without human interaction

End-to-end process chain for maximum productivity with SW machines

SW sees automation as a holistic task. From the delivery of raw parts to the loading of the materials in the storage tower, loading and unloading of the machine tool, and the removal of the finished machined parts, we’re focused on the entire process. A continuous process chain ensures maximum productivity.

We think in terms of scenarios that optimally reflect your requirements. Whether it’s a single machine or linked production line, CNC machining alone or with peripheral processes, the right combination turns loading units into productivity boosters.

Freely arrange

loading units

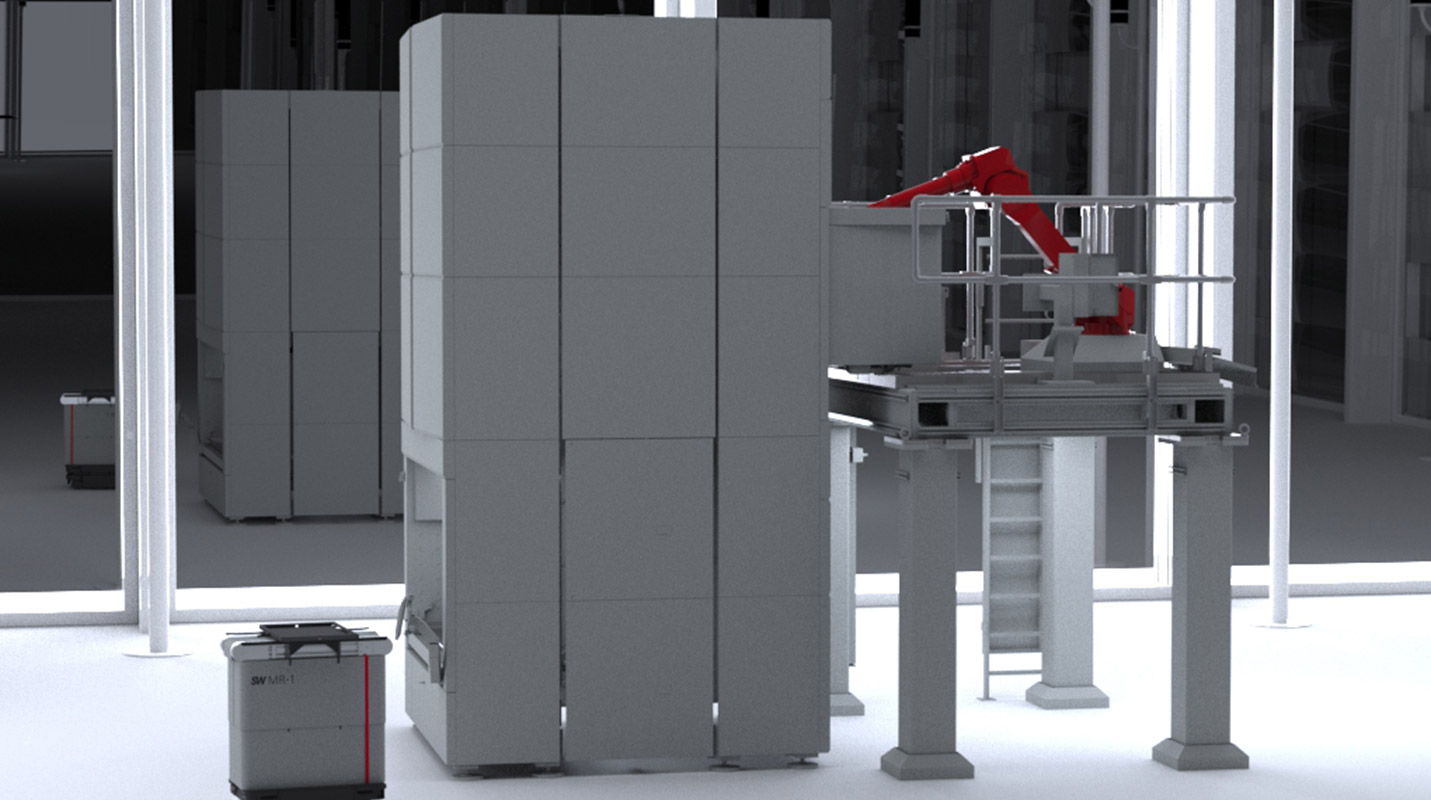

The “TopRob6” robots, which are scalable in terms of performance, and the storage tower are the central building blocks for efficient loading units. The storage tower and TopRob6 are linked to the machines via standard mechanical and electrical interfaces.

Vertical SW Storage Tower |

Very high autonomy with very small footprint |

Very high availability of the system |

Flexible to use, easily scalable for other tasks/processes |

Easy integration of value-adding processes (e.g. brushing, deburring, etc.) |

Manual loading of the machines easy possible due to excellent accessibility |

SPC workpieces, NIO workpieces or gripping systems can be managed in the |

standardized machine interface of the SW storage tower

You are entirely free to choose the composition and spatial arrangement of your loading unit and adapt it to your requirements. In addition, other combinations such as the operation of two machines by the same robot are possible. If production processes change, you can easily adapt the configuration with little effort.

Suitable for

unmanned

shifts

With loading units, SW machining centers can operate fully automatic over long periods of time and bridge unmanned shifts or shifts with low staffing while maintaining the usual high output. The Storage Tower can accommodate enough raw and finished parts for several hours of production. The workpiece carriers can be placed in, or removed from the corresponding compartments manually, or with the driverless MobileRob. The loading unit also automatically changes various fixtures and gripper systems.

SW Automation TopRob