World premiere at AMB 2022

The answer to new requirements?

New solutions.

This year’s AMB in Stuttgart is all about ‘Smart Manufacturing Solutions’ for SW. On a 357-square-meter stand, trade fair visitors can expect an exciting insight into the company’s product highlights ¬- including a world premiere with which the global player is thinking far beyond the standard of the manufacturing industry. “We see ourselves not only as a ‘machine provider’, but rather as a ‘solution provider’ that offers its customers intelligent, digitally networked, energy-efficient and future-proof manufacturing solutions – in other words, ‘smart manufacturing solutions’ consisting of our proven standard machine portfolio, modular automation modules and digital services,” explains Marketing Manager André Harter. Setting new benchmarks and actively shaping the future of the industry is the motto. Rapidly changing requirements in new industries, such as e-mobility, are opening up new potential for manufacturing solutions – which SW knows how to address. A SW expert will provide information on these and many other topics in live talks in front of a six-meter LED wall at the trade show booth.

World premiere: produce larger with the same footprint size

A special highlight at AMB 2022 will be the world premiere of the new BA 711 space – a flexible single-station machine for small and medium series production of precision parts made of cast iron, cast steel or steel. “The pure footprint is almost identical to previous models. But the new design eliminates the partition wall in the machine interior, so the space available in the machine has been expanded enormously,” explains Harter. So the BA 711 space has effectively not become any bigger, but it can now machine considerably larger parts, such as engine blocks, chassis parts or transmission housings for agricultural and construction machinery, trucks, rail vehicles and much more.

Looking to the future: why multi-spindle machines and automation modules are the right choice.

Industries such as e-mobility in particular place great demands on manufacturers in terms of flexibility and future viability. SW has been successfully supporting its customers in these areas for years, and has always focused on multispindle machining centers. This year at AMB, for example, the benefits of energy-efficient multispindle machines are once again coming to the fore. “A four-spindle machine shortens cycle times by up to 60 percent compared to single-spindle machines. At the same time, it saves around 70 percent of the footprint and consumes only about half the amount of energy,” says André Harter, citing important factors for a future-proof and sustainable investment. The latter in particular is ensured by the fact that SW also supports its customers with customized automation solutions that can be flexibly retrofitted. “Reducing non-productive time, increasing quality, improving ergonomics – with a modular system divided into hardware and software, we always find the optimum solution. In this respect in particular, I’m looking forward to interesting discussions at the trade show.”

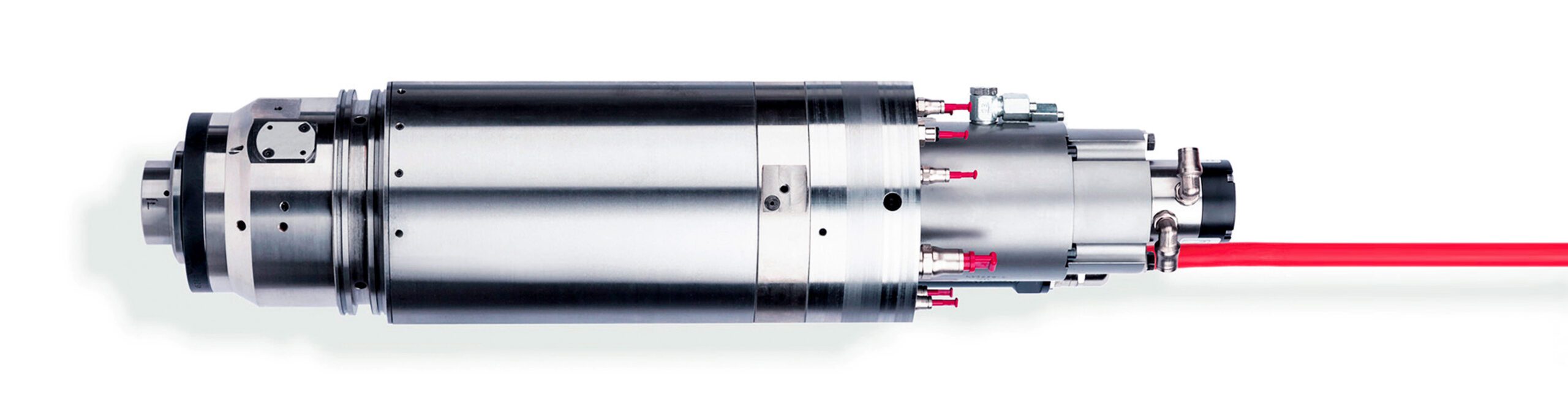

Market first: one interface for everything – made by SW.

This should make it clear: SW is increasingly profiling itself as a solution provider and holistic system partner. An important key component is digitally networked communication for optimum interaction between the machines, systems and optionally available add-on modules. For example, in order to be able to integrate energy-carrying tools into the machine tool easily and independently of the manufacturer, SW is presenting an in-house development at AMB: the HSKi spindle. “Our services range from intelligent interfaces for connecting external add-on modules with the help of our HSKi spindle to software programs and cloud solutions that enable greater transparency and data availability during manufacturing processes – that’s what we call life data at our company,” says Harter, summarizing the wide range of process optimization options. So there will be plenty to talk about, and the SW experts at the booth are already looking forward to it. This is what makes the difference between a ‘machine provider’ and a ‘solution provider’.