TechnologyMountains members visit Schwäbische Werkzeugmaschinen GmbH (SW). How does a global engineering company like SW deal with a possible upheaval in the automotive industry?

By successfully changing its own customer portfolio: How this is achieved at the Waldmössingen-based machine manufacturer was experienced by around 50 visitors who, at the initiative of the “TechnologyMountains” cluster initiative, were allowed to take a look behind the scenes of the manufacturer of multi-spindle machining centers and automation solutions.

Daniela Jardot, organizer of the evening from TechnologyMountains e.V., revealed right away in her welcome speech the successful role played by the host of this evening of the “Mountains Tour”. The use of multi-spindle machining centers for medical technology then also characterized the following explanations. Introducing the company, Managing Director Reiner Fries drew a picture of the boom that the mechanical engineering company has experienced in recent years: since the financial crisis in 2009, he said, sales have skyrocketed from 82 to 400 million euros, and the number of employees has grown from 289 to around 1,000 worldwide, 740 of them at the headquarters in Waldmössingen.

The majority of SW’s machines active worldwide can still be found in the production of automotive suppliers: Around 95 percent of the machining centers there ensure halved to quartered machining times per workpiece with high precision thanks to their parallel machining of two to four workpieces. However, more and more medical technology manufacturers are also taking advantage of this effect of shorter machining times, as Sales Manager Tobias Trautmann pointed out: “Because what works for turbochargers or connecting rods for the combustion engine also increases efficiency in the production of artificial hip and knee joints, bone plates or surgical instruments, thus significantly reducing their manufacturing costs. SW now generates around five percent of its sales with non-automotive manufacturers, and that is set to increase, as Fries indicated.

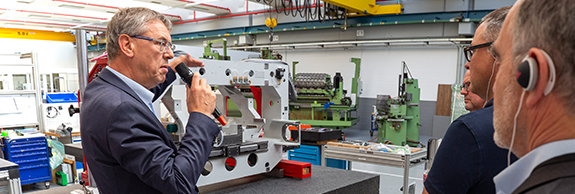

The interested guests then experienced how the production of the machining centers works at SW in tours of the manufacturing facility: Modular basic designs are already combined with customer-specific requirements in the factory and the machines are already run in with the appropriate clamping devices and first workpieces before the journey to the users begins. SW is present and successful with sales and service locations in 37 countries around the world, thanks in part to the high flexibility of its machining centers: Not only can they be equipped with modularly expandable tool magazines – currently, a magazine for up to 400 tools is being built at the customer’s request. SW also supplies the machining centers with loading modules with integrated automation, which loads and unloads workpieces by robot arm, thus ensuring unmanned shifts. The company also offers virtually seamless automation solutions for other tasks in metal-cutting production. All in all, the mechanical engineering company successfully creates an expanded customer spectrum through this versatility of its machines. The guests were enthusiastic about the possibilities offered by SW machining centers and took the opportunity to ask the experts questions during and after the tour.

Questions about the fair? Contact us, we will be happy to help!