Mobility and Modularity: How SW’s New S-Cell is Redefining Flexible CNC Automation

Manufacturing environments today demand agility. Shifting product mixes, fluctuating order volumes, and ongoing labor challenges are pushing manufacturers to find solutions that are not only efficient but also adaptable. While fixed automation has long been the go-to, it often locks companies into rigid processes that can’t keep up with change.

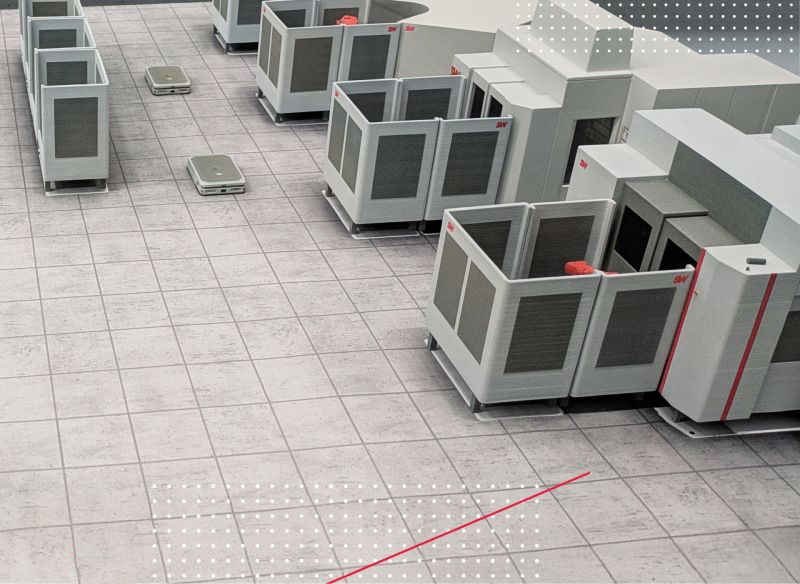

SW North America’s new Mobile S-Cell automation concept is aiming to change that—bringing modularity, mobility, and intelligence together in a way that helps manufacturers scale smarter.

What makes the Mobile S-Cell different?

Instead of being tied to one place or process, the Mobile S-Cell is a self-contained robot cell mounted on a mobile carrier system. It moves through the production environment using SW’s driverless transport system, the Mobile S-Wagon, and can dock temporarily at any number of stations—machining, washing, assembly, or even laser processing.

Once docked, the integrated robot with a precision gripping system takes over—loading raw material from Mobile S-Storage units, operating the station, and returning finished workpieces. The process is fully automated, freeing up operators for higher-value work.

Unlike fixed lines, the S-Cell doesn’t need to be permanently linked to its stations. When it’s not in use, the station remains accessible for cleaning, maintenance, or other operations—keeping production flow uninterrupted.

A smarter path to scaling automation

One of the biggest challenges for manufacturers adopting automation is balancing upfront investment with long-term flexibility. Fixed systems can be expensive to reconfigure when demand shifts, leading to costly downtime or unused capacity.

The S-Cell’s modular design flips that equation. Manufacturers can start with a single unit, then add more cells as capacity needs grow. With each cell able to handle payloads up to 120 kg (264.5 lbs.) and integrate with both SW and third-party systems, expansion becomes far simpler—and less risky.

“The flexibility of the S-Cell gives our customers a competitive edge,” says Andrew Rowley, General Sales Manager at SW North America. “They can start small, scale quickly, and adapt to change without massive capital investment.”

Designed for modern manufacturing realities

Industries with dynamic product requirements—like automotive, aerospace, or medical—stand to benefit most. In automotive alone, where parts like engine blocks, oil pans, or bushings can vary in volume and cycle time, multiple S-Cells running in parallel can maintain consistent throughput, even with cycles under 10 minutes.

And because the system is powered and controlled either by the station it docks to or via SW’s proprietary automation platform, manufacturers can ensure seamless data integration, traceability, and process reliability across the entire workflow.

Automation that moves with your business

As manufacturers look for ways to stay competitive, adaptable automation like the Mobile S-Cell offers a path forward. It’s not just about automating a task—it’s about building a system that can evolve with your production strategy.

To see how SW’s Mobile S-Cell and other automation solutions could fit into your operation, visit SW North America Automation Solutions.