SW Machines North America, Inc.

Open House & Technology Day

Future Built: Precision, Power, Possibility

August 8, 2025

9am to 3pm

30160 Lyon Industrial Court

New Hudson, MI 48165

Highlights

Facility Tour

Machining & Technology Demonstrations

Learn How To

Overcome labor challenges

Increase Productivity

Shorten Cycle Times

Elevate your Aerospace Manufacturing with the BA space3 equipped with with Linear Motor Machining Technology

Live Demonstrations

Medical machining demonstrations the BA W02-22

Tibial Insert / Femoral

Optical component machining demonstrations on the BA 322i

Aerospace machining demonstrations

on the BA space3

Technology Overview

Multi-spindle machining

Linear motor technology

Automation

Self-sufficient production cells

Plus, get an inside look at our spindle rebuild area within our Rotary Axis Group. Learn about our amazing apprentice program and our top-notch life Services.

Relax and mingle with other manufacturing professionals in our state-of-the art technology center while you enjoy a German beer or glass of wine and light German-American fare.

BA 322i

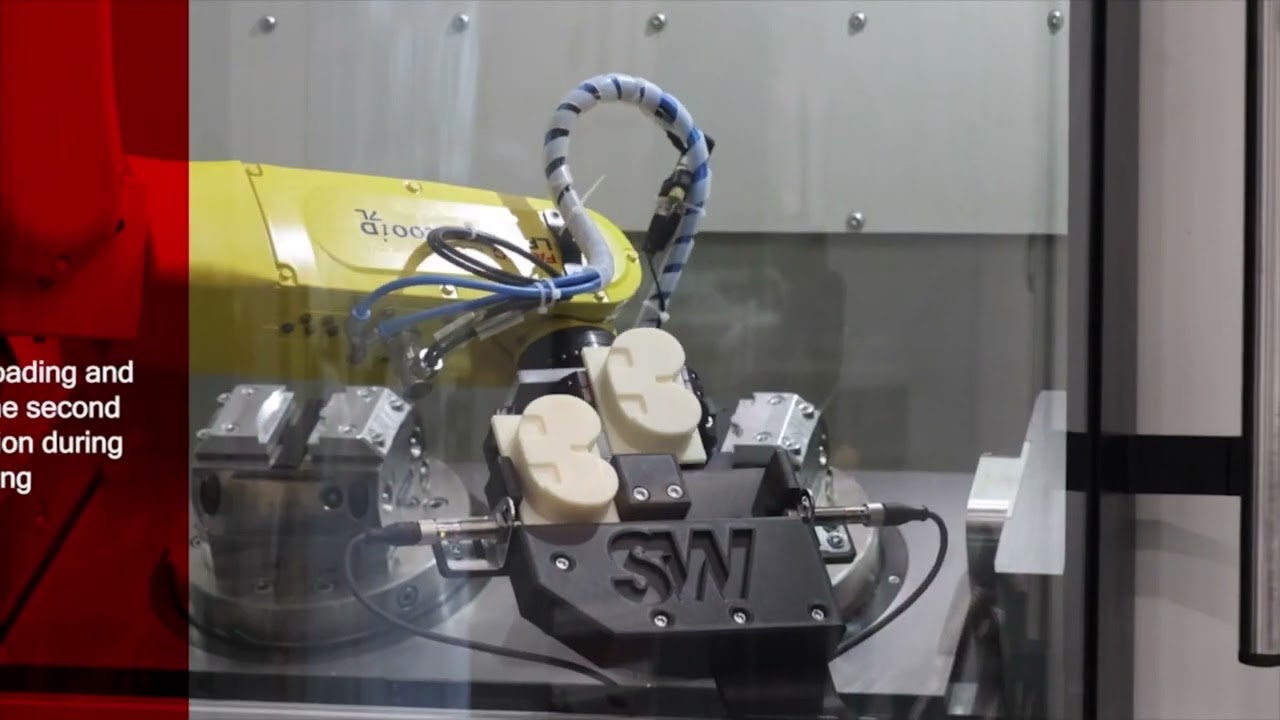

The BA 322i is designed to function as an independent manufacturing cell that can store enough workpieces for an entire shift.

This twin-spindle horizontal machining center doubles output while using less floorspace and less energy.

The integrated 6-axis robot utilizes the vertical workpiece storage tower to load and unload workpieces in parallel to machining time thanks to the double swivel carrier. The monoblock and box-in-box design are proven SW standards, providing more stability and precision.

This plug & play solution is perfect for the machining of impellers, brake calipers, scroll compressors, ABS valve bodies, optical components, and more.

BA 322i

| X-axis | 300 mm |

|---|---|

| Y-axis (tool change position) | 450 mm (725mm) |

| Z-axis | 375 mm |

| Spindle distance | 300 mm |

| Work Spindle | HSK-A63 |

| Speed Range | 1-10,000 rpm (1-17,500rpm) |

| Torque | 2×32 kW / 4,200 rpm / 2×72 Nm (40%ED) |

The BA 322i is designed to function as an independent manufacturing cell that can store enough workpieces for an entire shift.

This twin-spindle horizontal machining center doubles output while using less floorspace and less energy.

The integrated 6-axis robot utilizes the vertical workpiece storage tower to load and unload workpieces in parallel to machining time thanks to the double swivel carrier. The monoblock and box-in-box design are proven SW standards, providing more stability and precision.

This plug & play solution is perfect for the machining of impellers, brake calipers, scroll compressors, ABS valve bodies, gun slides, and more.

| X-axis | 300 mm |

|---|---|

| Y-axis (tool change position) | 450 mm (725mm) |

| Z-axis | 375 mm |

| Spindle distance | 300 mm |

| Work Spindle | HSK-A63 |

| Speed Range | 1-10,000 rpm (1-17,500rpm) |

| Torque | 2×32 kW / 4,200 rpm / 2×72 Nm (40%ED) |

BA SPACE3

BA SPACE3

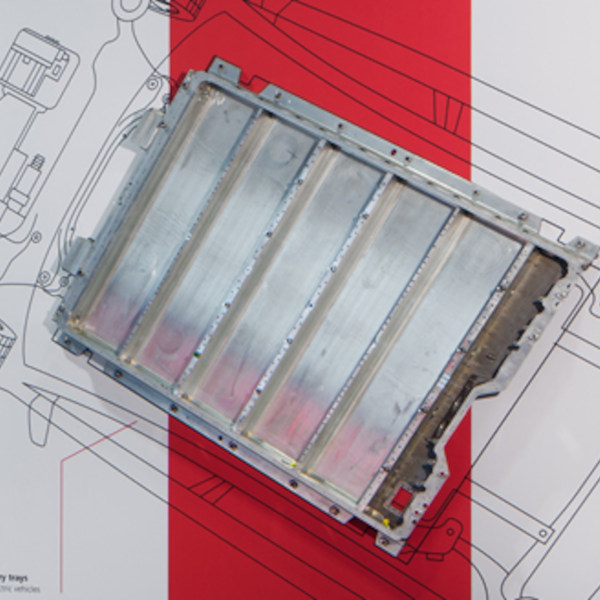

The BA space3 features a working range of 3,000 x 1,800 x 875 mm on the X-,Y- and Z-axes respectively for precise and efficient production of battery housings, subframes and other large structural components in the automotive, EV and aerospace industries. On each of these axes, the HSK 63 spindle can reach a rapid traverse of 120 m/min, with a chip-to-chip time of 4-4.25s.

| Workspace X-axis | 3,000 mm |

|---|---|

| Workspace Y-axis | 1,800 mm |

| Workspace Z-axis | 875 mm |

| Max. tool (-o-) | 80 mm /200 m (-o-) |

| Tool size max. length | 450 mm / 10 kg |

The BA space3 features a working range of 3,000 x 1,800 x 875 mm on the X-,Y- and Z-axes respectively for precise and efficient production of battery housings, subframes and other large structural components in the automotive, EV and aerospace industries. On each of these axes, the HSK 63 spindle can reach a rapid traverse of 120 m/min, with a chip-to-chip time of 4-4.25s.

| Workspace X-axis | 3,000 mm |

|---|---|

| Workspace Y-axis | 1,800 mm |

| Workspace Z-axis | 875 mm |

| Max. tool (-o-) | 80 mm /200 m (-o-) |

| Tool size max. length | 450 mm / 10 kg |

BA W02-22

Experience shorter cycle times and higher productivity with direct drives. Linear motors and torque motors generate the desired movements directly, without mechanical transmission elements and therefore operate wear-free and without mechanical backlash. The acceleration of linear motors is particularly important. In SW machining centers, they achieve acceleration values of up to 2g and rapid traverse speeds of 120 m/min. And this is with maximum precision.

Experience shorter cycle times and higher productivity with direct drives. Linear motors and torque motors generate the desired movements directly, without mechanical transmission elements and therefore operate wear-free and without mechanical backlash. The acceleration of linear motors is particularly important. In SW machining centers, they achieve acceleration values of up to 2g and rapid traverse speeds of 120 m/min. And this is with maximum precision.

Visit and Learn with

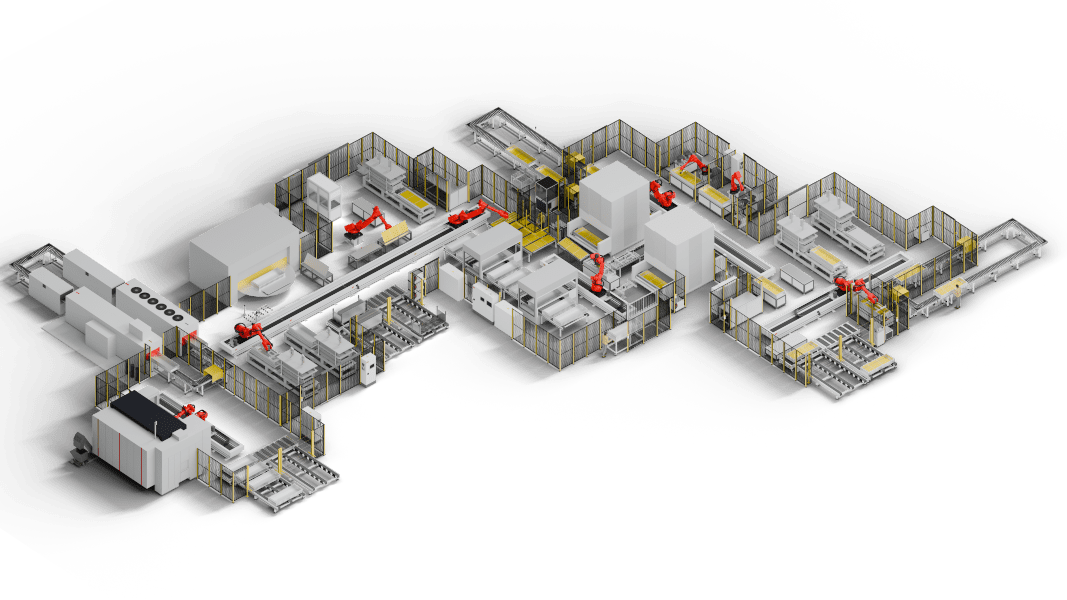

As part of our full-day open house event, we’re offering a series of in-depth informational sessions designed to provide valuable insights into the future of manufacturing automation and system integration.

Deep Dive: Industry & Automation Focus

Gain targeted insights through three optional sessions during our 2025 Open House. Each session explores key developments in automation, customer success in complex system integration, and emerging trends across medical, aerospace, and high-volume manufacturing. Designed for engineers, managers, and decision-makers, these focused discussions complement the day’s live demonstrations and plant tours.

Join us for the following expert-led presentations:

10:30 – 11:15 AM: Smarter Automation with Peter Andersson

10:30 – 11:15 AM: Smarter Automation with Peter Andersson

Peter Andersson, SW Product Manager for Automation & Assembly Systems, will share an inside look at SW’s cutting-edge automation capabilities. He’ll introduce our new S-Cell—a modular, scalable automation solution designed to grow with your production needs. A 30-minute presentation will be followed by 10–15 minutes of live Q&A.

12:30 – 1:15 PM: Real-World System Solutions – Customer Case Study

Hear directly from a top program launch manager at a Fortune 100 company—responsible for the largest system solution installation in their company’s history—as they share their experience implementing a comprehensive, plant-wide solution built by SW. Learn how our systems are transforming real-world production at scale. This session includes a 30-minute presentation followed by 10–15 minutes of Q&A.

1:30 – 2:15 PM: Aerospace Insights with Industry Media

1:30 – 2:15 PM: Aerospace Insights with Industry Media

Eric Brothers, editor of Aerospace Design & Manufacturing will present trends and opportunities in aerospace manufacturing, with a focus on automation, machining, and innovation. A 30-minute talk followed by 10–15 minutes for questions.

Highlights of Past Events

REGISTER TODAY

TRAVEL ACCOMMODATIONS

Holiday Inn Express

Rate: $110

Group Code: SWN

Booking Link

Or Call: 248 735.2781

Booking Deadline: July 20, 2025

HAMPTON INN EXPRESS Wixom

Rate: $115

Group Code: SW North America

Booking Link

Or Call: (248) 348-0170

Booking Deadline: 5:00 pm July 8, 2025.

Cancellation policy: written notice by August 5, 2025

Hyatt Place Detroit/Novi

Rate: $109

Group Code: G-SWA5

Booking Link

Or Call: 1-800-233-1234.

Booking Deadline: July 11, 2025

Airport:

Detroit Metropolitan Airport (DTW) is approx. 35min. from SW North America

Flint Bishop International Airport (FNT) is approximately 45min from SW North America.