E-mobility: Shaping the paradigm shift

Opportunities for established and new suppliers

Even if combustion engines will still be produced for many years, the shift toward locally emission-free e-mobility will continue to progress. This paradigm shift in the automotive industry is twofold. In addition to the established car manufacturers, countless newcomers are working on the development and establishment of series production of electric vehicles. Whether hybrid drive or fully electric with battery or fuel cell, the value chains are changing faster than most market observers expected Along with the established TIER 1 and TIER 2 suppliers, numerous companies are entering the market worldwide. They are developing new e-mobility components and rapidly building up production capacities. SW CNC machining centers combine productivity with process reliability and guarantee fast, high-precision, and scalable solutions for the production of components such as:

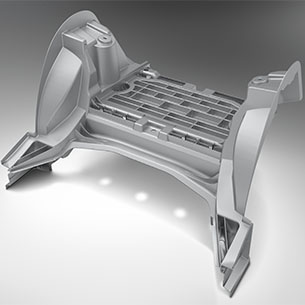

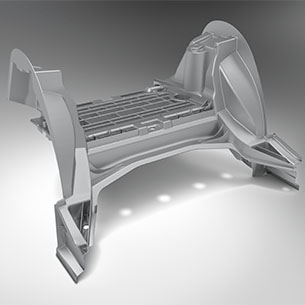

| Large-sized structural & frame components made of non-magnetic metals

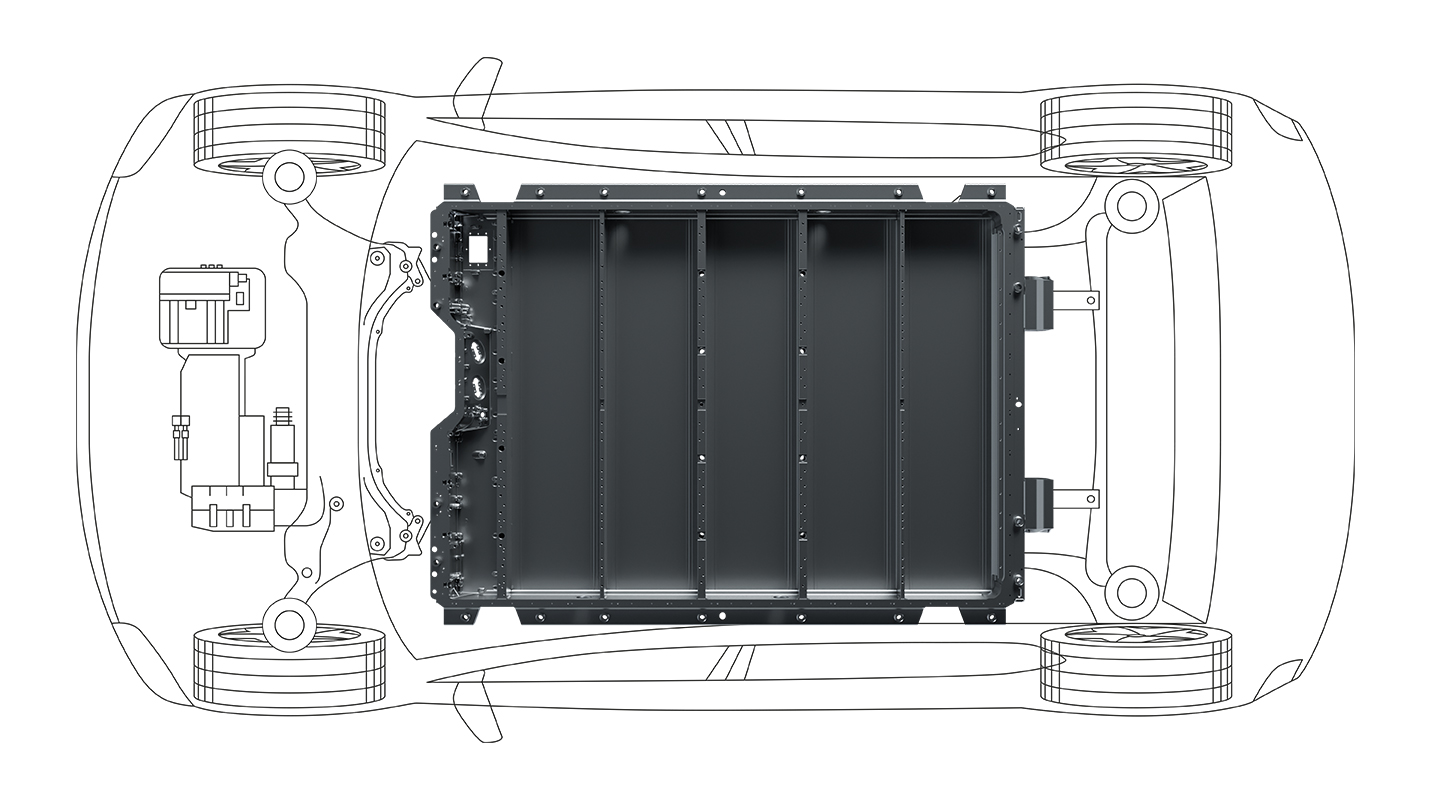

| Battery housings and battery trays

| Scroll compressors

| Stator housing

| Lightweight components

Reduce weight and increase range

In e-mobility, the weight of each individual component is even more critical to success than before. The lighter the vehicles, the greater the range. Our CNC machining centers with linear motors for light metal machining are among the fastest systems in the world. They reduce the chip-to-chip time by more than a quarter and accelerate the feed axes by 60 percent. SW CNC machining centers with linear motors lead in efficiency and quality in e-mobility and automotive production. You can cost-effectively manufacture new components for PHEVs, BEVs or FCEVs with high precision in small batches on single-spindle CNC machining centers from SW. You can also scale the quantities very quickly with validated processes on 2-, 3-, or 4-spindle CNC machine tools from SW in stable, reproducible quality. This is how you shape the paradigm shift toward e-mobility.

Large EV

Components

Our proven series cover the requirements for the multi-spindle production of components for e-mobility very well. In addition, with single-spindle CNC machining centers, we are opening up the precise machining of large structural components such as battery housings made of light metal with lengths of up to 3,000 mm with the usual SW precision and economy. This is how you shape the paradigm shift.

Reference parts