Manufacturing solutions for medical technology:

Reproducible precision meets productivity

Achieve perfect reproducible surface quality through high precision. The manufacturing of medical implants, instruments, components, or devices for medical technology always places high demands on surface quality. Manufacturing solutions from SW combine precision with productivity. SW machines, production cells, and systems ensure 100 percent traceability of all processing steps down to NC block level and integrate seamlessly into higher-level MES and ERP solutions of life science companies.

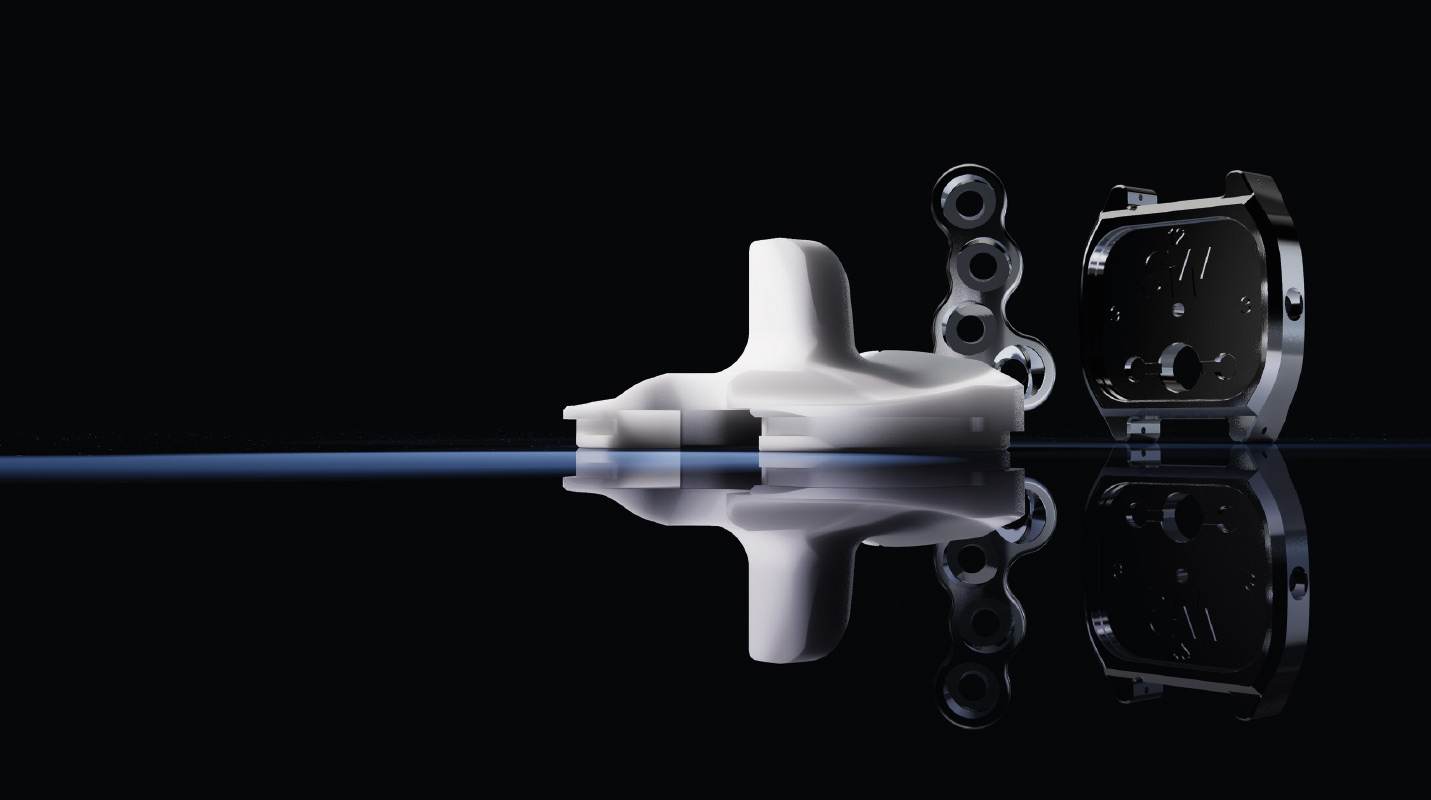

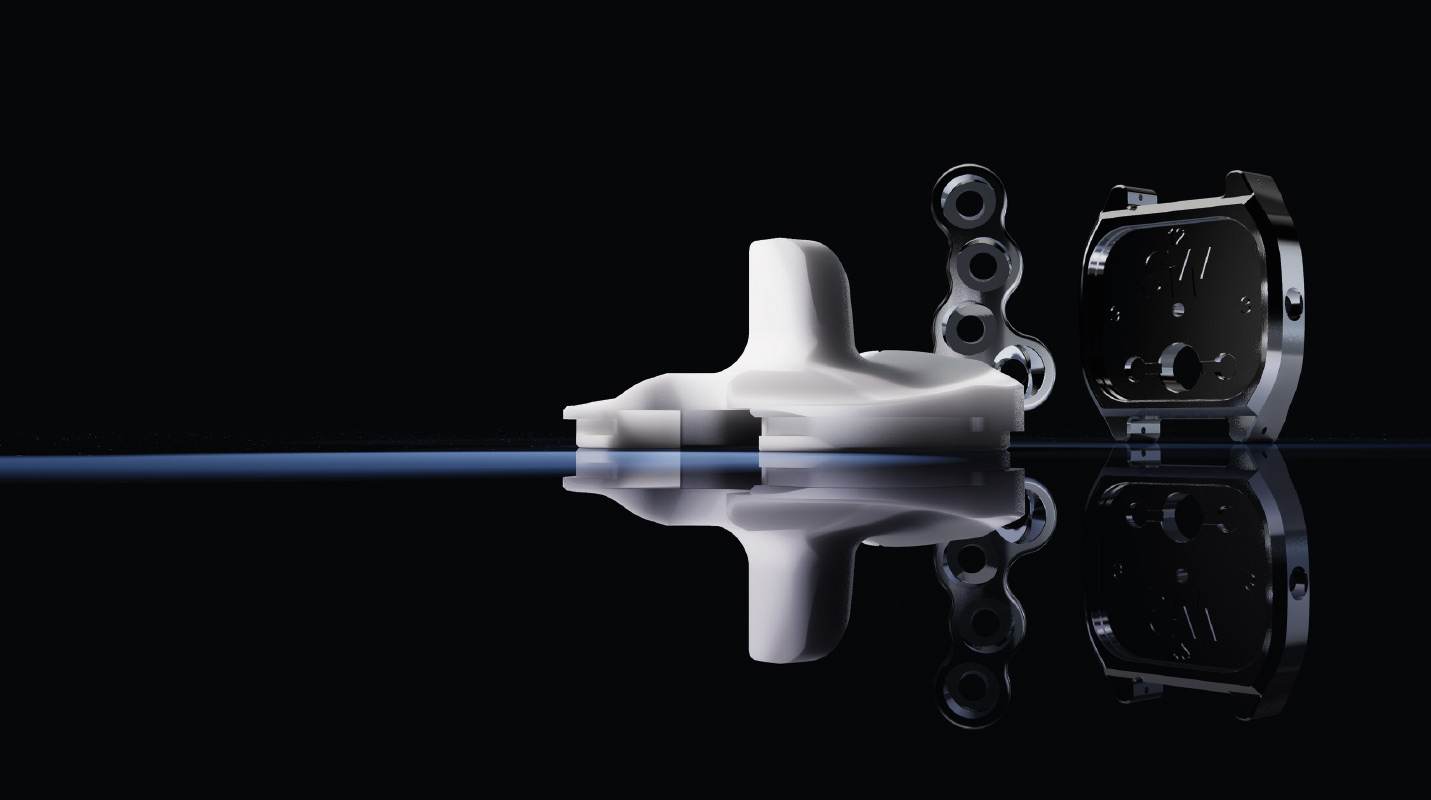

Whether square or round raw material, surgical steel, titanium, non-ferrous metals of all kinds or high-performance plastics: SW machining centers produce high-precision medical technology products and

| Surgical instruments such as scissors, forceps, punches, rasps or tweezers

| Components for endoscopic diagnostic devices

| Plastic and metal implants such as knee and hip joints and bone plates from joint and spine surgery and much more.

Clean thing: Free chip fall

SW machining centers are designed precisely to meet the requirements of medical technology production. Due to the horizontal spindles, the chips fall directly into the chip conveyor and not onto the workpiece. With linear motors for the feed axes, we set new standards for surface quality and precision for free-form surfaces. High speeds of up to 36,000 rpm in 5-axis simultaneous machining further enhance quality. Important additional effect: SW machines shorten machining cycles and chip-to-chip times with their high dynamics: Precision meets productivity. Alternative option of multi-spindle! Large tool magazines and smart changeover solutions round off the benefits.

Rooted in medical technology

In the immediate vicinity of SW, around Tuttlingen between the Black Forest and Lake Constance, is the center for medical technology production. Renowned companies have been developing and manufacturing surgical instruments, implants and medical devices here for decades, which are used worldwide. As a long-standing partner of these manufacturers, we at Technology People know how we can also create the conditions for higher precision and productivity in your medical technology production. We will be happy to carry out test machining for you and individually calculate the unit costs in series production:

| DESCRIPTION | 42,000 knee implants per year | 200,000 tweezers per year |

|---|---|---|

| Machine | BA W02-22 | BA 321 |

| Workpiece size | 80 x 55 x 45 mm | 250 x 30 x 10 mm |

| Material | Plastic | Aluminum |

| Cycle time per piece | 10 min. | 1.25 min. |

Transparency and

Traceability

inclusive

As an established equipment supplier to medical device and medical component manufacturers, we are very familiar with the regulatory requirements in the Triad markets. We supply machines tailored to life sciences including automation, self-sufficient production cells, up to complete production lines including all auxiliary processes. Our solutions always ensure absolute transparency, because they document every production step down to the NC block level. This enables you to achieve full traceability, and ultimately the validation requirements in your medical device production.

Reference parts