SW Machines North America, Inc.

Open House & Technology Day

10 Year Celebration

August 25, 2023

10am to 3pm

30160 Lyon Industrial Court

New Hudson, MI 48165

Highlights

Facility Tour

Machining & Technology Demonstrations

Learn How To

Overcome labor challenges

Increase Productivity

Shorten Cycle Times

Accelerate your EV Productivity with

Linear Motor Machining Technology

Live Demonstrations

Medical machining demonstration BA 322

See the TopRob7 in action: Automation for components manufacturing

Dry-cycle linear motor machining at lightning

fast speeds

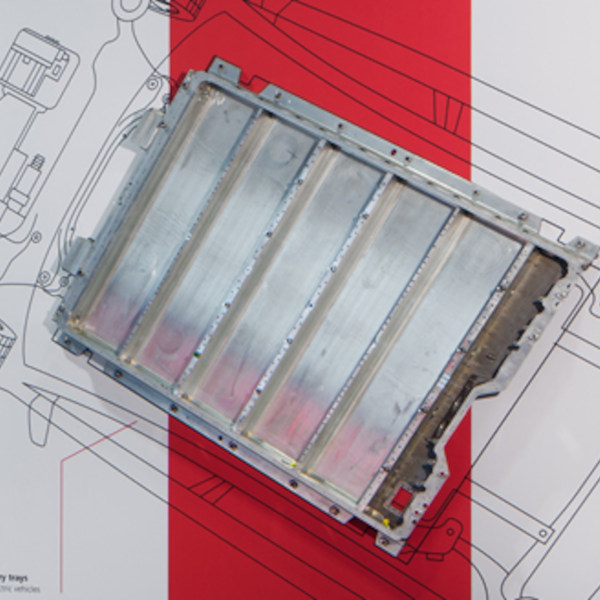

Experience our EV technology information center

Electric vehicle test drives

Technology Overview

Multi-spindle machining

Linear motor technology

Automation

Self-sufficient production cells

Plus, get an inside look at our spindle rebuild area within our Rotary Axis Group. Learn about our amazing apprentice program and our top-notch life Services.

Relax and mingle with other manufacturing professionals in our state-of-the art technology center while you enjoy a German beer or glass of wine and light German-American fare.

BA 322

BA 322

The BA 322 is designed to function as an independent manufacturing cell that can store enough workpieces for an entire shift.

This twin-spindle horizontal machining center doubles output while using less floorspace and less energy.

| Number of spindles | 2 |

|---|---|

| Spindle distance | 300 |

| HSK interface | HSK-A63 |

| Workspace X-axis | 300 |

| Workspace Y-axis | 450 |

| Workspace Z-axis | 375 |

| Tool size max. length (mm) | 300 |

| Tool size max. width (mm) | 450 |

| Tool size max. height (mm) | 375 |

The BA 322i is designed to function as an independent manufacturing cell that can store enough workpieces for an entire shift.

This twin-spindle horizontal machining center doubles output while using less floorspace and less energy.

The integrated 6-axis robot utilizes the vertical workpiece storage tower to load and unload workpieces in parallel to machining time thanks to the double swivel carrier. The monoblock and box-in-box design are proven SW standards, providing more stability and precision.

This plug & play solution is perfect for the machining of impellers, brake calipers, scroll compressors, ABS valve bodies, gun slides, and more.

BA W06-22

SW’s BA W06-22 is the perfect solution for machining large workpieces made of aluminum and other non-ferrous materials. This machine features two spindles, two worktables, and a work area of 600 x 900 x 650 mm on the X-, Y-, and Z-axis.

| Number of spindles | 2 |

|---|---|

| Spindle distance | 600 |

| HSK interface | HSK-A63, HSK-A80, HSK-A100 |

| Workspace X-axis | 600 |

| Workspace Y-axis | 630 |

| Workspace Z-axis | 510 |

| Tool size max. length (mm) | 600 |

| Tool size max. width (mm) | 630 |

| Tool size max. height (mm) | 510 |

TopRob7

TopRob7

Each SW machining center is a highly productive solution with the shortest cycle times. In production lines, it is important to further increase productivity by optimizing material flow and sophisticated automation into efficient complete processing from the raw part to the finished component. Conventional robots with six axes reach their limits here. Our solution is linking the machine tools and other stations via SW’s “TopRob7” 7-axis robot gantry.

Modularly expandable at any time |

Free accessibility and safety without protective fences |

Multi-sided reach down |

Main time parallel maintenance |

Cleanliness in production through integrated oil pan concept |

Each SW machining center is a highly productive solution with the shortest cycle times. In production lines, it is important to further increase productivity by optimizing material flow and sophisticated automation into efficient complete processing from the raw part to the finished component. Conventional robots with six axes reach their limits here. Our solution is linking the machine tools and other stations via SW’s “TopRob7” 7-axis robot gantry.

Modularly expandable at any time |

Free accessibility and safety without protective fences |

Multi-sided reach down |

Main time parallel maintenance |

Cleanliness in production through integrated oil pan concept |

Visit and Learn with

EV TEST DRIVES

Vroom vroom. No, make that buzz buzz. We are excited to announce that we’re partnering with Hines Park Ford of New Hudson, Feldman Hyundai of New Hudson, Suburban Volkswagen of Farmington Hills, and the Tesla Showroom of Troy to bring you an electrifying experience at our Open House on August 25th, at our New Hudson facility. Register now for our event and get the exclusive opportunity to test drive a variety of electric vehicles, including the Tesla Model Y, Ford Mach-E, Ford F-150 Lightning, and more.

Highlights of Past Events

Ready for some gridiron fun in the D?

Two tickets for the Detroit Lions home opener vs the Seattle Seahawks on September 17 will be offered during the event at 1:30pm, must be present at that time to receive.

REGISTER TODAY

TRAVEL ACCOMMODATIONS

Hotel:

Room for guests at: Hyatt Place Detroit / Novi, 46080 Grand River Avenue, Novi, MI 48374 Get directions

Reservations can be made by calling the hotel at +1 248 513 4111. Enter Group Code G-SW23 in the booking link to reserve a room. Room availability is limited at a rate of $119/night plus tax and up to 20 rooms.

Room for guests at: Hampton Inn & Suites Wixom 49025 Alpha Dr, Wixom, MI 48393 Get directions

Reservations can be made using the booking link below or by calling the hotel at +1 248 348 0170. Use the booking link to reserve a room. Room availability is limited at a rate of $112/night plus tax and up to 20 rooms.

Room for guests at: Holiday Inn Express Wixom 48953 Alpha Dr., Wixom, MI 48393 Get directions

Reservations can be made using the booking link below or by calling the hotel at +1 248 735 2781. Use the booking link reserve a room. Room availability is limited at a rate of $110/night plus tax and up to 20 rooms.

Airport:

Detroit Metropolitan Airport (DTW) is approx. 35min. from SW North America

Flint Bishop International Airport (FNT) is approximately 45min from SW North America.